Manufacturing Success

Great Plains Packaging has built a solid reputation in the industry. Through the use of innovative technology, state-of-the-art manufacturing facilities, and award-winning design, we create solutions that grab attention, stimulates purchase behavior, and contributes to your overall bottom line.

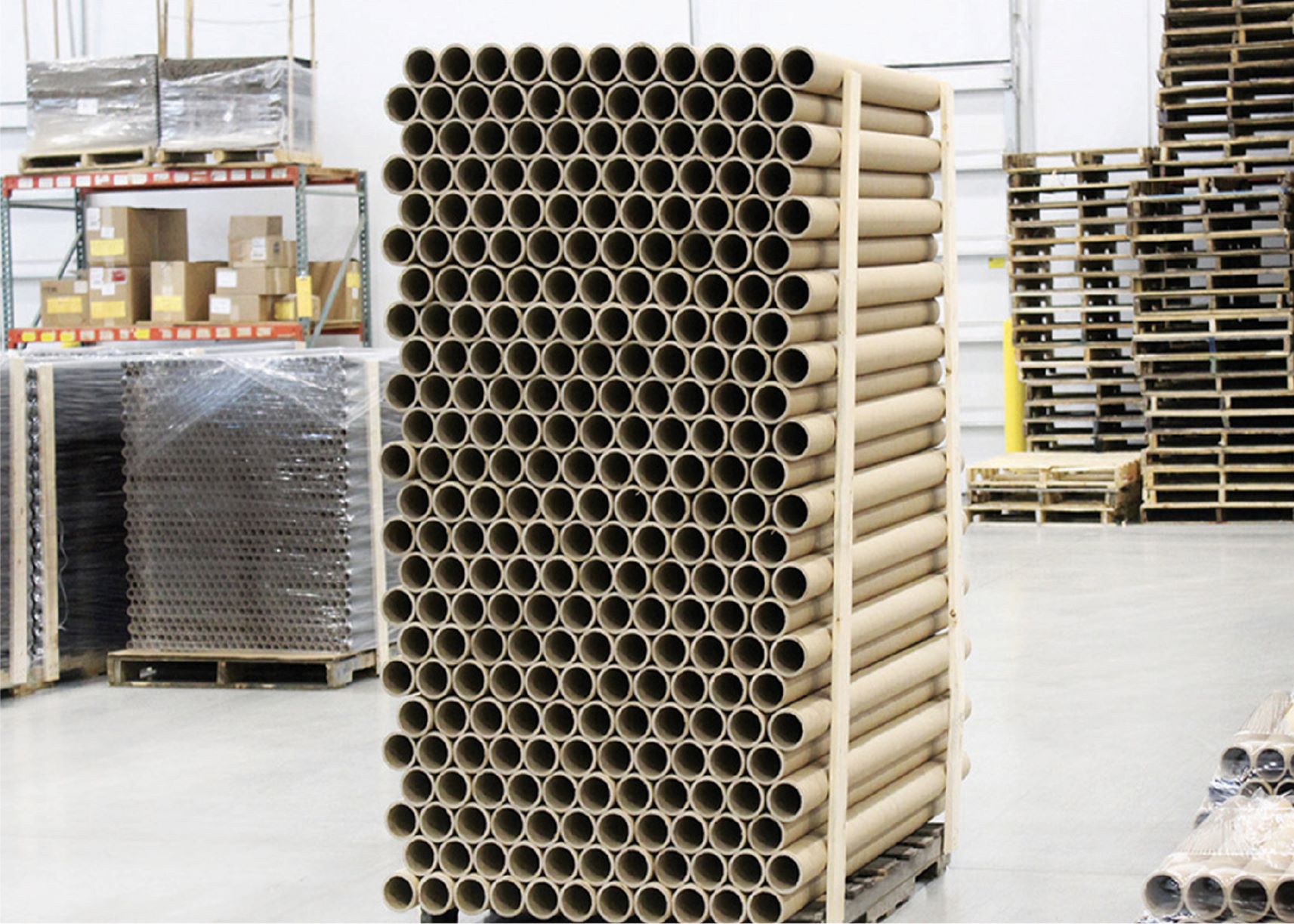

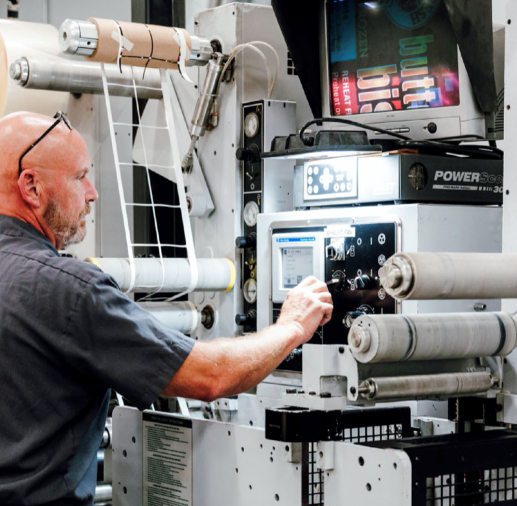

Manufacturing Equipment

When it comes to production, the old adage “time is money” is an understatement. Our equipment list includes redundancy in nearly every area, an invaluable peace of mind during critical production time. From digital printers and litho laminators, to die cutter rotary and flexo printers, we’ve got your covered. Contact us today to learn more about our in-house manufacturing capabilities.

Reliable, Consistent, and Trusted Partner.

Great Plains Packaging can handle tight timelines with a quick response to meet your deadlines.

Delivering reliable, consistent solutions and service through:

- Redundancy through all our facilities, manufacturing, and printing equipment.

- Capacity through high-speed manufacturing equipment and continuous investment in improvements.

- Efficiency through advanced systems, innovation and technology for faster turnaround times and quality control.

- Safety through our commitment on facility upgrades and safety programs to improve our work environment and keep our team safe on the job.

Vanguard Packaging

Your partner for award-winning turnkey merchandising solutions, custom packaging, POP displays, and multi-brand programs.

Vanguard Digital™

Our digital printing enables in-line, high-speed and on-demand capabilities.

Vanguard Companies is one of the first in the world to install HP’s new ground-breaking C500 technology. The benefits of our digital printing include lower minimal order quantities, less inventory management, improve in-hand marketing, variable print, no printing plate cost, faster speed to market and use of water-based inks.

With the PageWide C500’s single-pass thermal inkjet technology and direct-to-board advanced media handling we optimize the entire production floor with the flexibility to print one to thousands of boxes even with last-minute changes. We can quickly run packaging and display campaigns in offset quality without the need for lamination. Consistently superb quality is possible on both coated and uncoated papers.

ALF®

Independently owned logistics and fulfillment company specializing in display assembly, packout, kitting, special packs, and contract packaging.

- Display Assembly & Contract Packaging

- 425,000 + Sq. Ft. Temperature Controlled Facility

- 45 Shipping and Receiving Dock Doors

- Flexible Staffing Model / Adjust to Customer Needs & Seasonality

- Hand Assembly & Automation Equipment

- Multiple Fulfillment & CPG Certifications

- 24 hr. Secure Facility with over 90 Surveillance Cameras

- Warehousing & Inventory Management

- Program Management / Planning Teams

- Quality Control / On-Site Quality Staff

- Logistics / Regional, DC’s or Direct to Retail

International Operations

Our Asia design and manufacturing facility is home to our design and project management teams, along with a dedicated Quality Control and Co-Packing division. This facility is part of the Corrugator Network in China and conducts ISTA Testing in China.

- Manufacturing Offset & Flexo Printing Facilities

- Ability to Direct Print off the Corrugator

- Fulfillment (Southern, Southeastern & Northern Regions)

- Working Relationships with Walmart Global Sourcing

- General Lead-Time is 2-3 weeks

- Container Lead-Time is 4-6 weeks

- Extensive Network of Partners Across Asia and Europe

The ever-changing retail landscape with the rise of ecommerce offering increased product choices and categories, coupled with internal company challenges, are driving the need for an efficient and effective supply chain to support customer demand.

Our goal is to provide a mutually beneficial relationship with a high-level of service. At Great Plains Packaging both sides systematically control the availability and flow of goods to anticipate and meet consumer demand to grow their business.